Innovation Of UV Technology

Lighting Up UV Is Easy,

Ensuring Their Lasting StableHigh Performance Take Expertise!

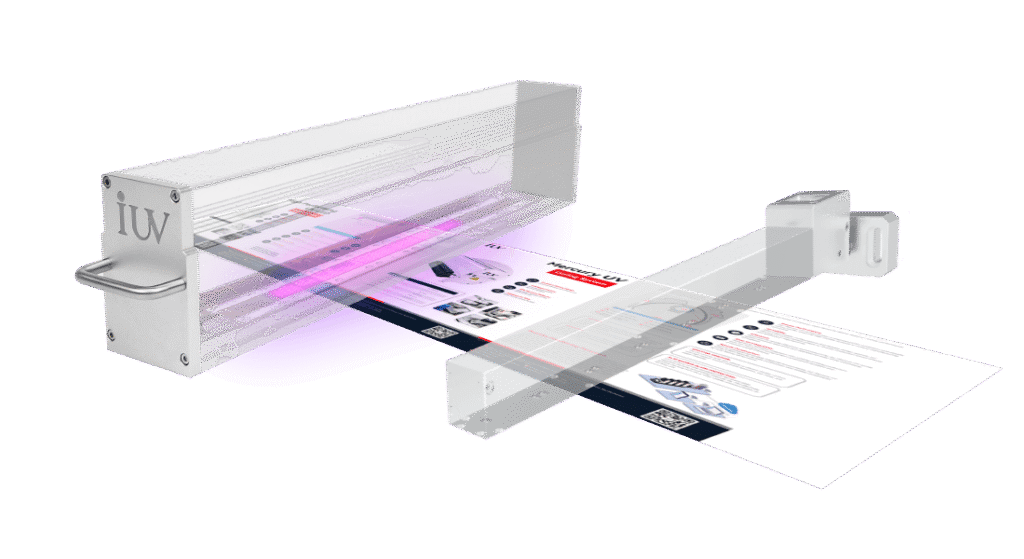

Automatic Sensing Technology

Automatic material sensing technology is a combination of IUV modular technology and digital control technology.

It can automatically sense the position and width of the printed material in real time, and automatically control the working area of the entire LED UV curing system in real time based on the material width and position data.

Con tecnología de detección automática, las IUV — With automatic sensing technology, IUV provide an energy saving effect of over

70% energy saving compared to traditional mercury UV lamps.

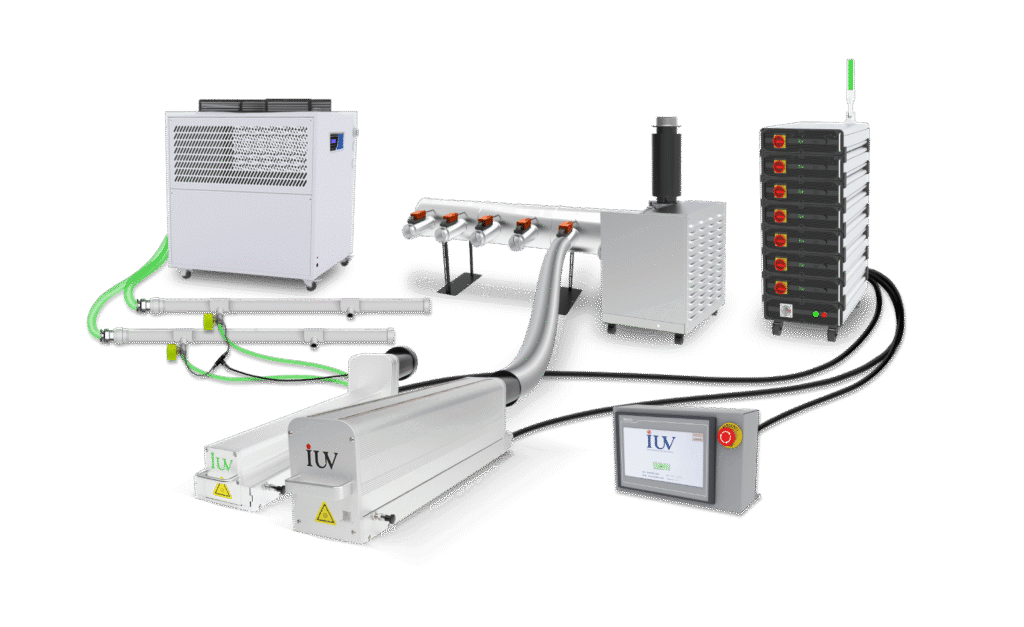

Modular Power Supply System

IUV’s Modular Power Supply System, designed to enhance UV curing process with advanced features:

Constant Voltage-Current Control: Ensures onsistent voltage and current for reliable performance.

All-in-One Intelligent Independent Control: Each unit operates in the form of independent, allowing seamless alability.

Automatic Monitoring and Diagnostic: Real-time monitoring diagnostic capabilities enable proactive maintenance, minimizing downtime and ensuring continuous, efficient operation.

Experience unparalleled stability and intelligence in your UV curing system with our Modular Power Supply System.

Cooling Technology

Cooling technology is the key of uv curing system stability and lifespan.

IUV has carried out precise design of cooling system and heat path at the beginning of design, and strictly selected the most suitable cooling method for you according to the needs of curing system and printing process, so as to ensure the most suitable and high-quality cooling effect with the highest cost performance.

With years of practice and research, we have customized an efficient water cooling system for LED UV and the most suitable air cooling system for mercury UV.

Remote Monitoring Function

This system offers a robust solution for seamless integration of IUV devices worldwide with a secure cloud-based platform. Leveraging internet connectivity, this system facilitates real-time data collection, fault detection, software updates, and more, accessible through both PC and mobile devices.

Designed for precision and operational efficiency, this system enables rapid diagnosis and resolution of technical issues, ensuring minimal disruption to production workflows.

Highlight it delivers comprehensive, real-time performance metrics, supporting data-driven decisions for optimized digital factory management and sustained operational excellence.

Explore More

4 lampes UV LED (1,6 kW) : IUV assure d’excellentes économies sur Nilpeter FB

Nilpeter

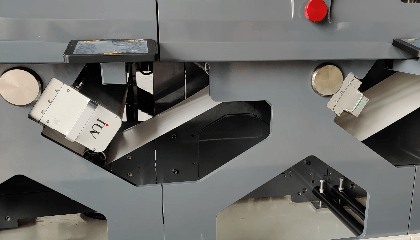

Revolutionizing Flexo Printing withInterchangeable UV curing

OMET

The project’s success with IUV ability to enhance print quality, increase productivity, and sustainability.

Bobst

With IUV’s LED UV curing system, enhanced production capabilities, and sustainability.

Gallus

IUV’s LED UV retrofit for fast curing , energy savings, and extended equipment lifespan.

Mark Andy

The UV LED upgrade for the MPS EF-430 is a testament to efficiency and sustainability.

MPS