Hybrid

UV Curing System

Lighting Up LEDs Is Easy

Ensuring Their Lasting Stable High Performance Takes Expertise!

Specification

| Specification ARC | |

|---|---|

| Irradiance At Window | 160 ~ 220w/cm |

| Lighting Length | 20 - 200cm |

| Optimum Curing Distance | 10 ~20mm |

| Cooling Method | Air Cooling |

| Expected Lifetime | >1000 Hours |

| Working Temperature | 40℃ |

| Specification LED | |

|---|---|

| UV Energy (w/cm²) | 18, 25, 30 w/cm² |

| Lighting Length | 10 - 200cm |

| Peak Wavelength (nm) | 365, 385, 395nm |

| Cooling Method | Water Cooling |

| Expected Lifetime | >30000 Hours |

| Working Temperature | Below 40℃ |

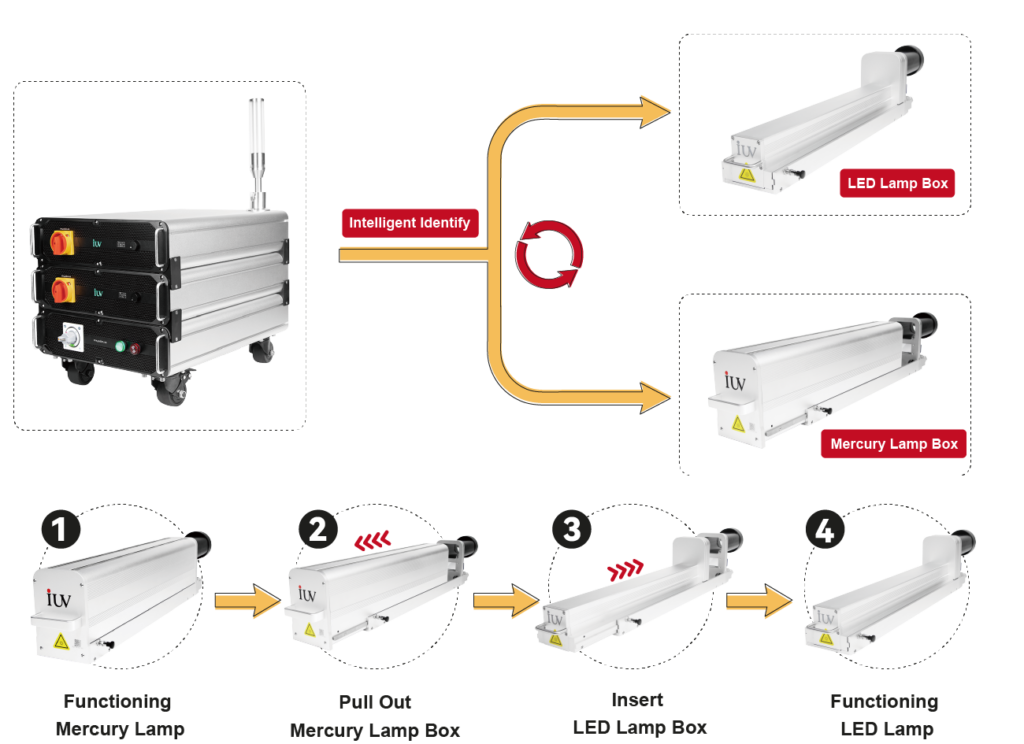

Freely Change Between LED UV & Mercury UV

How Does the Hybrid UV Curing System Work?

Why Do You Need LED Mercury Hybrid UV Curing System?

Easy Replace Of Hybrid UV

Intelligence Of Software Control

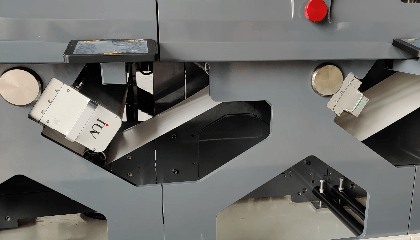

Strong Compatibility

Of Combination

High Return

Of lnvestment

4 lampes UV LED (1,6 kW) : IUV assure d’excellentes économies sur Nilpeter FB

Nilpeter

Revolutionizing Flexo Printing withInterchangeable UV curing

OMET

The project’s success with IUV ability to enhance print quality, increase productivity, and sustainability.

Bobst

With IUV’s LED UV curing system, enhanced production capabilities, and sustainability.

Gallus

IUV’s LED UV retrofit for fast curing , energy savings, and extended equipment lifespan.

Mark Andy

The UV LED upgrade for the MPS EF-430 is a testament to efficiency and sustainability.

MPS