Mercury UV Curing System

From printing and coating to adhesion and bonding applications,

IUV’s mercury UV curing system offers a trusted solution for enhancing productivity.

Specification

| Product Name: | IUV Mercury UV Curing System |

| UV Energy: | 160~220W/cm |

| Lighting Length: | 20-200cm |

| Optimal Distance: | 10-20mm |

| Cooling Method: | Air Cooling |

| Lifespan: | >1,000 Hours |

| Wide Applications: | Flexography Printing, Digital Printing, Intermittent Offset Printing, Letterpress Printing, Sheet-fed Offset Printing, etc. |

About Mercury UV

In printing, IUV’s mercury lamp curing systems offer rapid and efficient curing of inks, ensuring vibrant, long-lasting. It work with flexographic, lithographic, and screen printing inks etc,.

- Coating Applications:

In coating, IUV’s mercury lamp curing systems provide optimal curing for various coatings such as varnishes, protective finishes, and decorative layers.

In adhesive, IUV’s mercury UV systems excel in industries such as electronics, medical devices, and packaging. Enable bonding of materials like glass, metal, plastic, and composites.

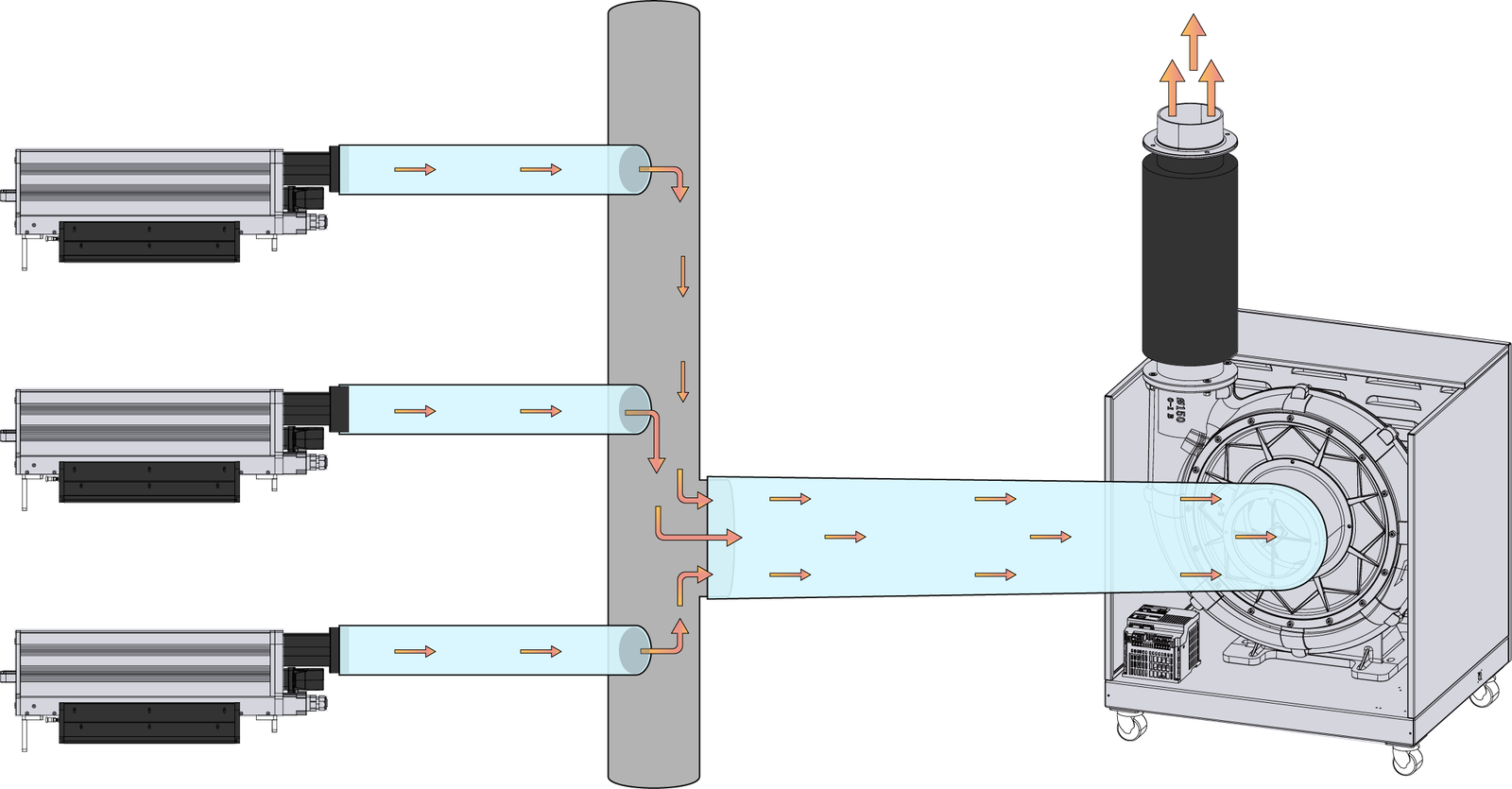

Why Mercury UV Takes Air Cooling?

Unlike LED UV systems, Mercury UV requires a specific temperature range to operate efficiently. Air cooling helps maintain the ideal operating temperature with heat, ensuring consistent and reliable performance over time.

Air-cooling systems are generally more affordable than water-cooling alternatives. With lower initial setup costs, they eliminate the need for additional water cooling infrastructure, making them a more budget-friendly choice for many businesses.

Air-cooling systems are highly adaptable and can be easily integrated into existing UV curing setups. They offer greater flexibility in installation and placement, allowing businesses to optimize their systems without the need for extensive modifications.

What Make IUV Mercury UV Curing System Different?

Proven Performance. Versatility. Efficiency. Ease Of Integration. Robust Construction.

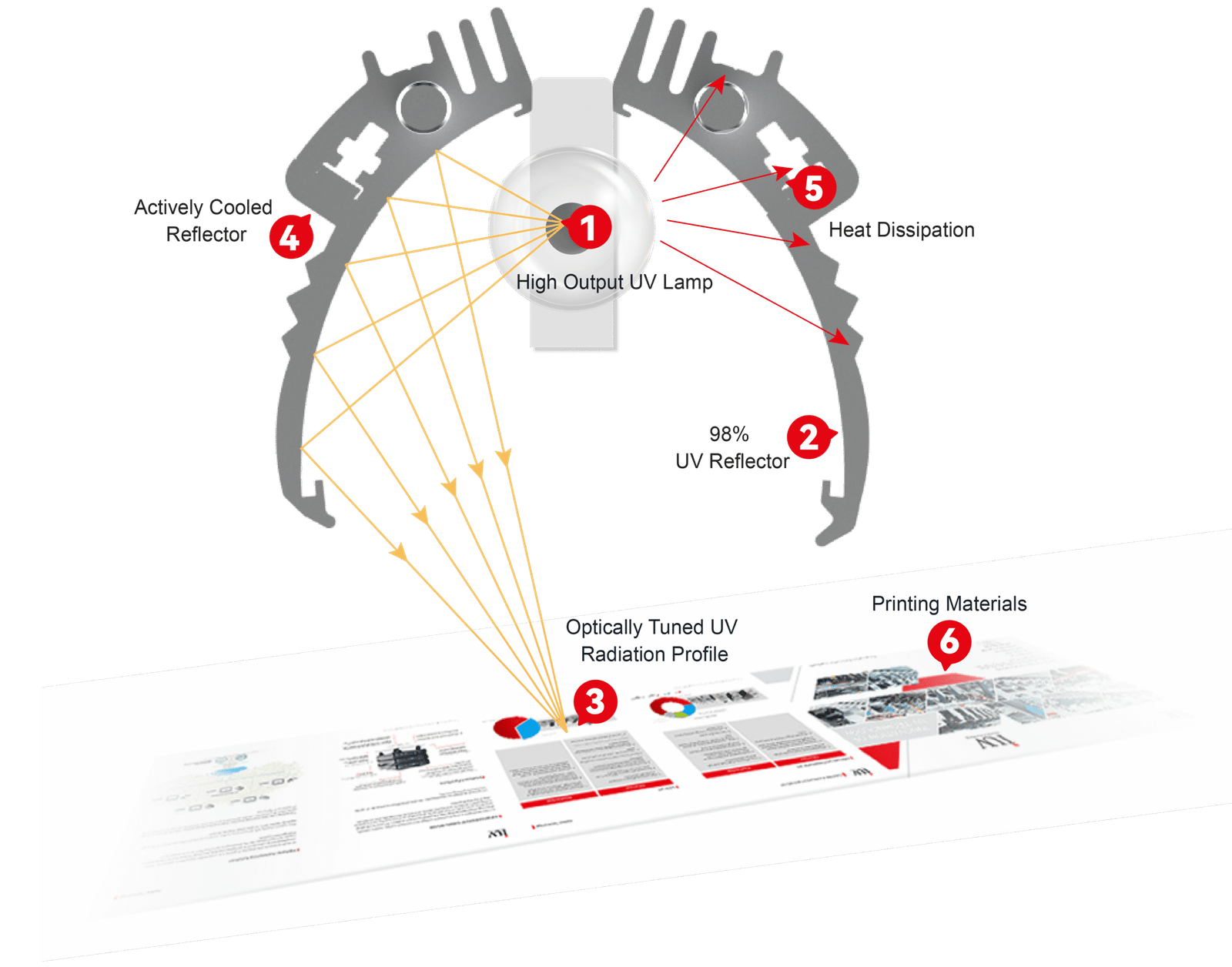

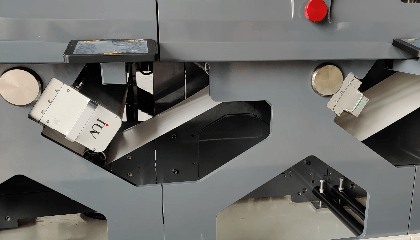

Optimized Heat Dissipation Path Design

IUV's mercury lamps feature an advanced airflow design that effectively expels heat from the lamp housing. This ensures that optimal operating conditions are maintained for good-balanced curing performance.

Smoothly Controlled Shutter

IUV's mercury lamps are equipped with an electrically controlled shutter that operates with high torque, delivering smooth, gentle movement with minimal noise.

This tech is able to keep stable and reliable operation, reducing the frequency of part replacements and enhancing the system's longevity.

Highly Efficient UV Reflector

IUV uses mirror aluminum reflectors that effectively reflect up to 98% of the light source.

Compared to reflectors using coated quartz glass, mirror aluminum provides superior curing performance and lower replacement costs, offering a more cost-effective solution while maintaining high energy efficiency.

Quartz Glass Protection

IUV mercury lamps are equipped with flat quartz glass that isolates the mercury lamp from the printing materials.

This protective layer effectively shields the lamp from contamination caused by inks or other volatile solvents, ensuring a longer lifespan and maintaining the lamp's performance over time.

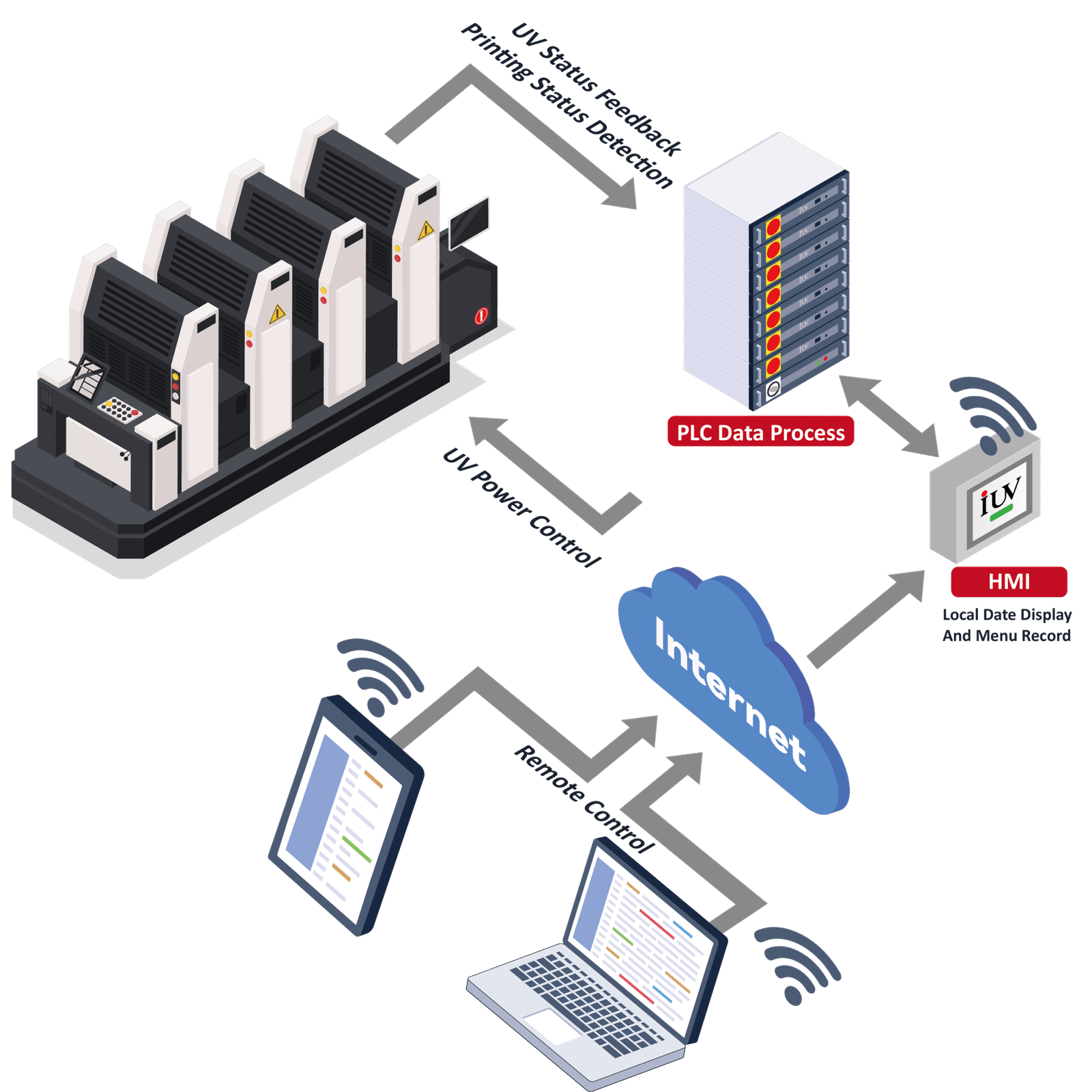

Cloud-local Data Interaction

- To ensure the seamless operation of IUV equipment worldwide, IUV has developed a comprehensive remote-local data link management system. This system facilitates efficient troubleshooting, remote OTA software upgrades, and supports future digital management needs for global customers.

- The IUV system enables equipment across the globe to connect to the cloud server via network cables, Wi-Fi, and other internet access methods. Through either PC or mobile phone, users can easily access real-time data collection, fault diagnosis, and software updates from anywhere in the world.

- This advanced system benefits customers in two key ways: first, it allows for quick identification and resolution of system issues, minimizing downtime and maintaining production efficiency; second, it provides real-time data to support the digital management and optimization of customer factories, helping businesses improve operations and make data-driven decisions.

4 lampes UV LED (1,6 kW) : IUV assure d’excellentes économies sur Nilpeter FB

Nilpeter

Revolutionizing Flexo Printing withInterchangeable UV curing

OMET

The project’s success with IUV ability to enhance print quality, increase productivity, and sustainability.

Bobst

With IUV’s LED UV curing system, enhanced production capabilities, and sustainability.

Gallus

IUV’s LED UV retrofit for fast curing , energy savings, and extended equipment lifespan.

Mark Andy

The UV LED upgrade for the MPS EF-430 is a testament to efficiency and sustainability.

MPS